Customer Services

Copyright © 2025 Desertcart Holdings Limited

🖨️ Flex Your Print Game with Magnetic Precision!

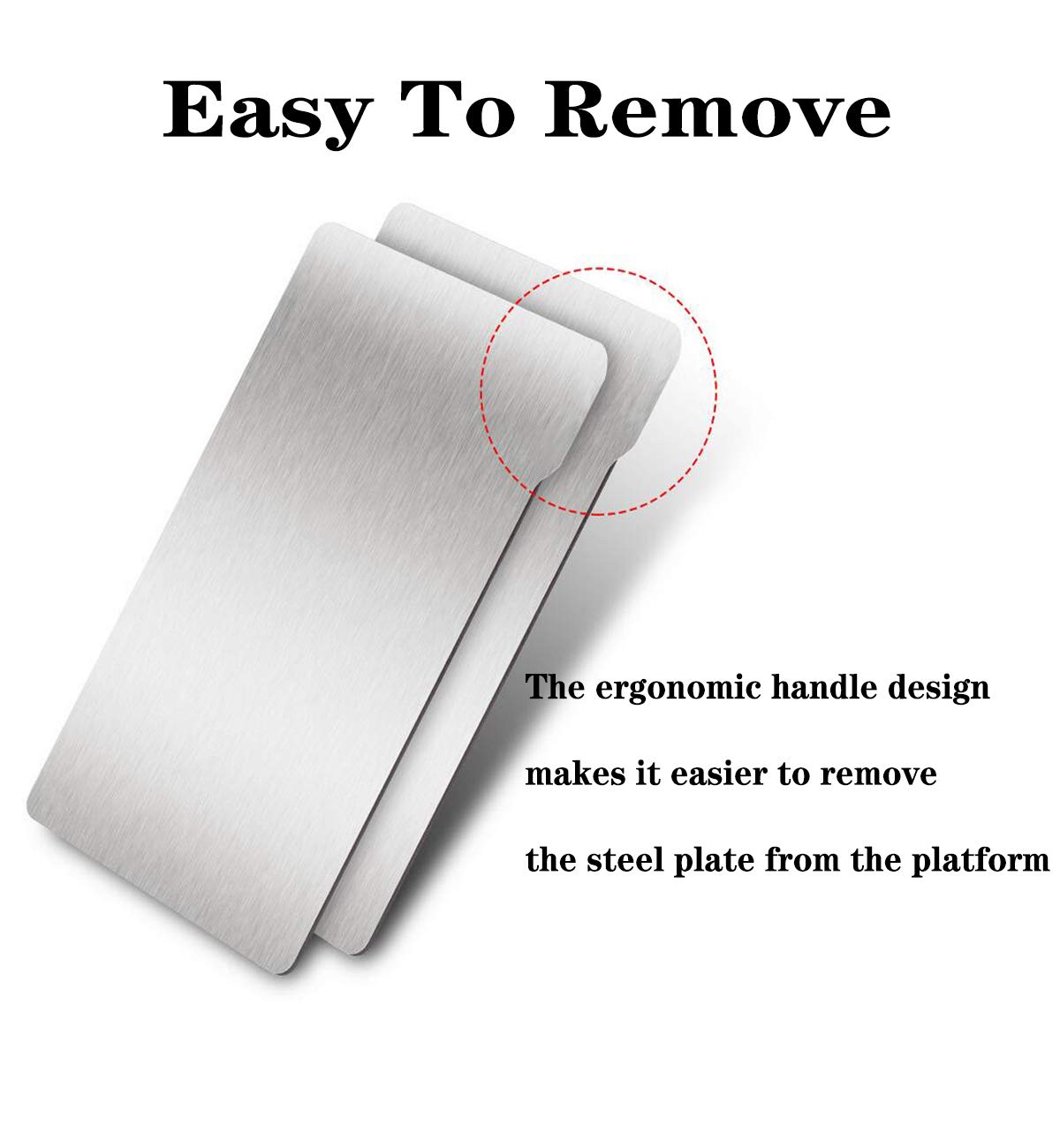

The KOYOFEI 2PCS Resin 3D Printer Flex Build Plate set is engineered for Anycubic Photon Mono 2 users seeking flawless print adhesion and effortless model removal. Featuring a precision 160x95mm spring steel plate with a CNC-machined magnetic base, this durable, flexible platform enhances print reliability and longevity. Its ergonomic handle and detailed installation tips ensure quick setup and professional-grade results every time.

| Manufacturer | KOYOFEI |

| Part number | KYF-3D-026 |

| Item Weight | 431 g |

| Package Dimensions | 24.99 x 15.8 x 1.19 cm; 431 g |

| Manufacturer reference | KYF-3D-026 |

| Size | Mono 2( 160*95mm) |

| Colour | Siliver |

| Material | Stainless Steel |

| Batteries included? | No |

| Batteries Required? | No |

P**R

Best accessory for the Saturn

Best accessory you can get for the Saturn printer. So much easier than manipulating the heavy build plate. Now I only need to remove the plate when tilting it to let resin drip off more effectively. I put the plate back on the printer after 15 minutes or so then peel off the stainless steel sheet. Easy to use, wash and prints come off really easy yet they are firmly attached to the sheet until flexed.Well made and fits perfectly.Just watch your fingers when snapping it back onto the build plate!Very highly recommended. Just make sure you get the right size.

K**R

Sand it and it works

Needs a rub down with some sandpaper to get prints to stick, but after that works fine.

C**D

Prepare to have to modify your printer for this to fit...

So, first, the good:- The 3M adhesive appears to be genuine and provided you leave it 48hr in a vice, the magnetic base adheres to the build plate- The sizing is good for the Phrozen 8K Mini. Not absolutely perfect, but good enough that if fitted correctly, the removal tab won't foul the sidewall of the resin vat.- The strength of the magnet is just right. Nice and strong; it's early days for me using this, but between this strength and the relatively small build plate, I'm fairly confident it won't suffer the lateral movement mid-print that plagues similar solutions on larger printers.- The Spring Steel Flexible plate is good. Again, not perfect, but good. The edges are not sharp, there's no evidence of burrs/similar that need to be removed.Now, the reason why it's 2 stars:- The magnetic layer is *much* too thick. Even on an otherwise completely stock printer with no other modifications, this uses up *more* than 'all the available' vertical adjustment on the build head.Annoyingly (not this product's 'fault', but it made it even harder to diagnose), for me, the z-axis calibration with a single piece of paper still worked as usual after fitment of this Flex Build Plate.The bed sensor got triggered as usual.Then, you go to print for real with the resin tank in place and the bed sensor *doesn't* get triggered. Meaning the build plate continues to grind downward, potentially damaging your screen and/or burning out your printer's motor. Not good.The problem is that the Flex Plate it uses up every last micron of adjustment. Yet, the FET in the base of the resin tank is fractionally thicker than a single sheet of A4 paper. So, the paper test makes you think all is fine, but when the Resin tank is in and filled with resin, it is fractionally too thick.The 'Fix':Twenty minutes of *very* carefully filing the holes shown in the attached image, then studiously cleaning all swarf off with alcohol, then re-assembling everything, re-calibrate and it all works.Yet, it's a pretty bad 'fix'. Whilst it now at least works:- There's still no adjustment left. Temperature changes alone could easily move this outside tolerances.- Replacing the FET with a fractionally thicker replacement FET/nFET, or using slightly heavier resin and you'd be back to it not working.- Adding a screen protector (a sensible mod and common mod on the Mini 8K) would further decrease the available Z-axis space and compound the problem.Yes, you could *further* file out the holes in the diagram above even deeper to restore more adjustment to accommodate the above, but doing so would further weaken/destabilise the vertical arms where these holes are and at least theoretically, would decrease print quality.Another alternative fix I could potentially see (but have not yet tried) would be to modify the printer's bed sensor so that it is ~1-1.5mm higher and so kicks in sooner.Request to makers of the Flex Build Plate:- Use a ~1-1.5mm thinner magnet.- Even then, warn users in the instructions and item description wherever it is for sale, that if they have also used screen protectors, etc. they might need to perform the above fix.Request to makers of the Phrozen Mini 8K:On the one hand, once users are modifying your product, all bets are off and it's on them. On the other...Wherever there is adjustment in engineering, unless there is a clear tendency to travel in one direction (opening up, or closing up); you try to make it so the adjustment ships dead centre. All popular modifications to the Mini 8K, however, decrease z-axis space. IE we can identify that have a tendency for them to 'close up' as they are modified. So, design the space for the hole I'm proposing modifying above, to be sited so there is only 25% adjustment in the direction of 'opening up', but put the other 75% adjustment available in the direction of 'opening up' (existing hole sizes would probably be fine, if this was done).This way, after the common mods are done, there will still be some adjustment available in either direction.I hope that this helps someone else and saves someone else hours of head scratching, investigation and emptying/cleaning the resin vat unnecessarily! :-)----Update----Rating now downgraded to one star.After only 50 hours of use...I noticed a strange bulge in one of my prints. On closer inspection, the magnetic layer was coming away from the base plate. The adhesive failed. Resin had gotten in behind it. Peeling the flex plate off, the magnetic layer came away (see photo above).Yes, I followed all the instructions and left it in a large desk vice for 72 hours to 'set' before using it. Now trying again with the second adhesive magnetic sheet; this time, leaving it for a week, before using it. If the second one fails inside of six months, they're going back.

A**N

Does not work without a simple printable fix. [SONIC MINI 8K]

As noted in other reviews the sticky-back magnet is waaaay too thick. The height the Z height sensor triggers places the plate below the height of the screen and that is a problem.Thankfully I found a little 3d Printable "Spacer" on certain Cult websites - find one, glue it on and Wham - it works perfectly!The plate is pretty sturdy and I really like it over previous plex plates I've used.

J**Z

Worked!

After reading a ton of reviews and tutorials I decided to give it a try, because scraping has been an absolutely nightmare for me. I use an Elegoo Mars 4.The set up was not easy (it's the understanding part which was hard), but still a lot easier than scraping.Basically 3 things;1, Insert a spacer for the Z sensor. It can be anything that's between 2.6-2.8mm thickness. I laser cut it out of a 2.7mm sheet.2, Relevel the build plate.3, Sand the steel plate surface.Then follow the instructions with the magnet and it's good to go.First print success!5 stars for now, but will update as soon as anything (adhesion, magnet, print) falls off.

A**A

Arrived on time and fits perfectly

Great fit for my saturn 2 8k, no issues with adhesion and arrived on time. Great value for money

R**S

Easy to use, clean and Mount

I bought this along with my Mars 3 (sadly they don’t do a Mars 3 sized build plate…yet) so I lost a little build area. I was pleased to see it had genuine 3M adhesive tape to hold it on! Might be teaching people to suck eggs but be sure to wipe the original build plate with IPA before mounting! Also the extra thickness of the magnet base will probably require a small spacer for Z homing, thingiverse probably has one for your machine.

R**D

Not up for the task

I do a ton of 3d printing, and I finally decided to get a flexible printing sheet. I've seen that they work, that youtubers and such use them.This doesn't work. It's very thin, possibly too thin so it flexes when printing. And it's literally a sheet of polished steel. Nit sandblasted, but pure polished metal. Even when I sanded it off my own back I got fails.5 fails with it on, anything that didn't have a huge raft on it didn't even stick to the plate and those that did weren't sticking properly. I immediately removed it and the magnetic strip, and tried the same print that I tried with it on. I have a full success, so all the fails were definitely due to the plate. Avoid.

Trustpilot

2 months ago

3 weeks ago