Customer Services

Copyright © 2025 Desertcart Holdings Limited

🖤 Black Magic for Next-Level 3D Printing Precision

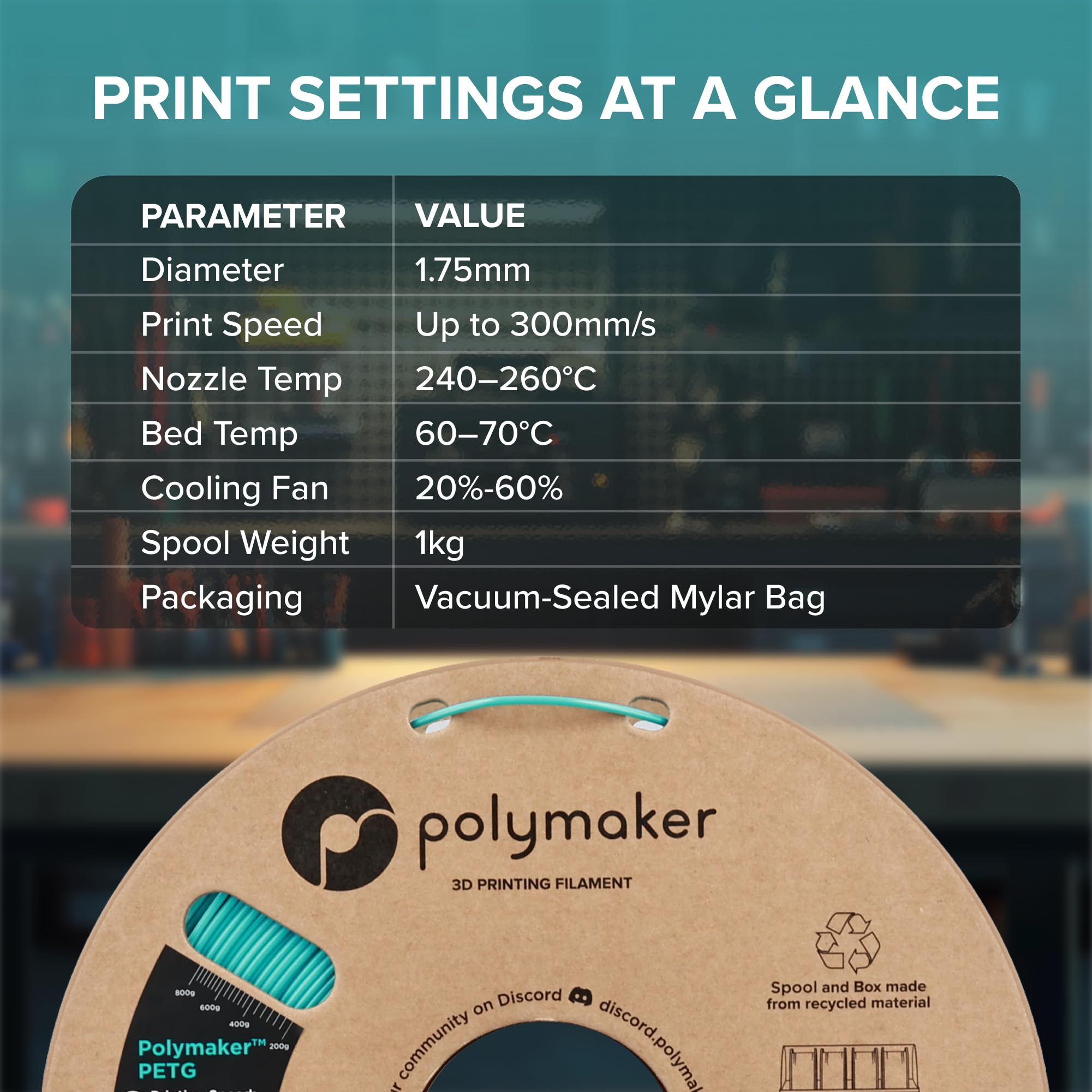

Polymaker PETG Black 1.75mm filament delivers a high-speed, high-strength printing experience with excellent layer adhesion and warp-free results. Compatible with most FDM printers and AMS systems, it’s vacuum-sealed for freshness and engineered to withstand up to 80°C, making it perfect for durable, functional prototypes and end-use parts.

| ASIN | B0FG3HMCVY |

| Best Sellers Rank | #503 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #52 in 3D Printing Filament |

| Brand Name | POLYMAKER |

| Color | 111 - 1.75mm Black (Hex Code: #070908) |

| Customer Reviews | 4.1 out of 5 stars 1,869 Reviews |

| Item Height | 6 centimeters |

| Item Weight | 1 Kilograms |

| Manufacturer | Polymaker |

| Material Type | Polyethylene Terephthalate Glycol |

D**S

Prints slow and hot, but very nice in the end.

Came in a mylar vac sealed package. Very robust. Didn't dry it at all, just threw it into the printer and ran a benchy to start off with and see how the stock settings in the profile from the Polymaker website worked. Flawless. Literally zero defects right out of the package. It prints fairly hot at 255C, with a bed temp of 70C, and very limited cooling. The volumetric speed is about half the newer version (non legacy), and the line speed also quite slow relative to the polymaker HF PETG. It prints beautifully with a nice glossy sheen. Not a fan of the lower speed it needs, but the results were quite good.

R**T

Quality Filament!

So far I have only used the Black PETG (apparently the old formula) I have a few colors to try. I don't have a single complaint yet. Out of the bag and straight to printing, it's been loaded on my printer for prototyping some speaker podz for over a week now and still doing good. Pros compared to other brands I've tried: - Hardly any stringing at all - Smooth prints with a nice sheen - Layer adhesion is good - Spool is neatly and tightly wound - Yet to have a tangle - Does not appear to be AS brittle The only con I can find is it does not seem to handle bridging as well as the previous brand I was using.

J**V

New formula makes this my favorite rapid PETG

The new formula is great. It’s basically high speed PETG but I love the color, quality and durability I get from it. Just make sure you dry it before printing as PETG absorbs moisture was faster than PLA.

C**S

Purple makes it terrible

A little bit of background: I've used Polymaker's PETG before, in translucent clear, and that's been a fantastic filament printing on my Ender 3 Pro with direct drive, E3D Revo with a .8mm nozzle and even on a textured PEI bed, no problems with that at 35mm/s - 55mm/s. Prints are strong, mostly warp free and look good aesthetically. For reference, the pictured prints were attempted on my Voron V0.2 with an E3D Revo with a .6mm nozzle, albeit quite a bit faster at around 100mm/s, which while faster than the recommended print speed on the spool, is no problem for other brands of PETG and PLA, those prints come out clean and well defined. Which is why it's baffling that the purple PolyLite PETG is so, just, bad at sticking to itself. It warps at the edges almost instantly, overhangs are completely hopeless, bridging is fine only if there's a single layer, any more than one layer of bridging and it'll shift the other lines of filament and cause even more problems. What looks like overheating layers seems to either be what it is, or a large lack of filament adhesion to itself in general. I tried to slow down the prints, down to about 60-70mm/s, but even then, the filament struggled to adhere to other lines and layers below past a certain point, telling me at least that there seemed to be an odd heat creep issue, which was more apparent in the temp tower, with sagging overhangs and bridges getting worse as the nozzle was getting cooler. Is it being printed too quickly? I'm not too sure, but there's not really any reason to pick this at all for modern printers that can print decently quickly if that's the issue. Pick any other PETG, even other Polymaker PETGs, especially the clear, unless you really need this color for some reason.

L**Z

Results are good, but holy cow it makes you go so slowly

The color is nice, it comes in the same kind of bag that Corn Pops come in, and it was dry from the factory. There's even a preset in Orca for this exact filament! The only reason to take the star off is: 1. The spool says to print at 230 to 240. The 4 3DBenchys I tried to print in that range disagree with that. My K1 SE wants to print this at 255 with a 70C bed. 2. The spool ALSO says that the print speed should be between 80 and 100mm/s. That's not a lie. If you go too fast, everything either strings, warps, or tears into the part with reckless abandon. 3. So far, seams look pretty rough, but that's going to require tinkering with Orca settings. Speaking of Orca, the default settings for Polylite PETG have it set to print at 255C on an 70C bed, contradicting what's printed on the spool. Overall, the print quality is good, if you can get past it taking 3x as long as other PETG's. It is dimensionally accurate, at least.

J**E

Best Filament Ever

Quality and reliability of this PETG is very high, compared to many brands. Have used and will use on many projects. This is my GO TO filament when needing strong parts. Does not string very much, and is a good buy for the cost. Failure is very uncommon when using correct technique.

K**N

Go to PETG

I do not write reviews often but in the case of this filament, absolutely. I have always used Hatchbox for my PETG needs, but no longer. The filament was shipped in the normal brown Poly box but vacuum sealed in a non-reusable bag. That is ok with me because I knew when I opened the package, the hiss let me know it was sealed correctly. As always, dry out your filament, especially PETG. I let this run at 54c for 8 hours before using. This is not my first translucent filament but it has been the EASIEST to print with. Stringing is basically non-existent, adhesion is not a factor and the quality of the prints are immaculate. I have tried countless filaments over the years from all manufacturers. Poly is my go to PLA using PLA Pro or Polylite because I have never had one issue with their filaments, so why not try their PETG. Yes this comes in a cardboard roll which I am fine with. Right now I am printing this with heavy infill because I need the strength but the transparency is VERY good even with 40% infill. Printing with a larger nozzle, less infill, thicker walls, and post-processing will give you a clearer finish. Print this slower than PLA. You can also go down to .1 and REALLY slow printing for a very clear finish, but will lose strength and time printing. PETG can be a little tricky if you do not have the correct temps / retractions. Surprisingly, I print this at a lower temp than other PETG filaments. I am running a Titan Direct Drive so my retraction settings will differ from a Bowden setup. I have printed this with Marlin without issue and currently running Klipper with BETTER results. Setup: Creality CR10-v3 STOCK Bed: G10 When printing on Glass I raise 5c Cura Settings for a stronger PETG print (Currently using settings for fan ducts for Hero Me G7) .4 brass nozzle .2 layer height .4 line width 1.2 wall thickness 2 Top Surface Skin Layers Monotonic Top/Bottom Unchecked Skin in Z Gaps Unchecked Ironing Unchecked 40% infill Connect Infill Lines Unchecked Temp 235 Build Plate 80 Initial Layer Bottom Flow 108% Print Speed 40mm/s My Titan Extruder Retraction settings Enable Retraction Retract at Layer change Checked Retraction Distance .8 Retraction Speed 45mm/s Retract before outer wall Checked Limit Support Retractions Unchecked Enable Print cooling UNCHECKED <---------- With Klipper, turn off all Acceleration Control, Jerk Control, Z Hop when retracted. Take your time with the Klipper setup and go through each step in order, not skipping. If you walked through all Klipper settings, everything will print GREAT. If not, blame the user and not the tools. I skipped a couple the first time through and was so confused as to why everyone loved Klipper because my results were terrible. Impatience got me. I went through the setup again (took my time, couple days), and I am sold. I will not go back to Marlin. For a good print, everyone should make sure a couple of things are in order regardless of slicer, firmware or printer... 1. Your bed is level 2. No seriously, take the time and level your damn bed 3. Do not write bad reviews because filaments do not stick to your unlevel bed 4. ESTEPS. Tune them, per roll, not per filament. It can change from roll to roll. Also, tune your ESTEPS at the temperature you are going to print at (start a spreadsheet and keep track of settings to cut down on the time it takes when changing rolls). 5. Correct temperatures. This can also change PER ROLL and depending on how dry it is. If you hear a slight pop sound, too much moisture. 6. Bed adhesion. I have used Carborundum glass beds, thick mirrors, HomeDepot 12in mirrors and now G10. There is ONE common factor to all of them, do not touch the bed. EVER. Wash the bed with dish soap and water, then dry with a clean, lint free cloth. Glass beds would require me to clean them every few prints. G10, pfft. I just wipe it down with the blue shop roll paper towels and done. Now if I TOUCH the bed, I clean it with dish soap and water. You can also use 99.99% alcohol to wipe the beds down as well. Spend $20 and get a G10 sheet. You will not be sorry. Happy Printing!

A**R

Not my favorite

After seeing a lot of advertising and people being paid to promote this brand, I was excited to try it. Compared to Ellegoo or bamboo lab the stuff is way harder to print with. For whatever reason sometimes it doesn’t wanna stick sometimes it doesn’t wanna hear on the after the first layer, but there was five print failures for every one successful project. This trail filament didn’t make me want to try more of this variety when it did work printed really good, but not better I’d say than other brands of filament I tried changing print settings and tuning it and while I did get some good prints, most the time for whatever reason or various reasons they would fail. I had a lot of spaghetti monsters a lot of adhesion issues that common remedies didn’t fix or weren’t needed on other filament varieties.

Trustpilot

2 months ago

1 day ago